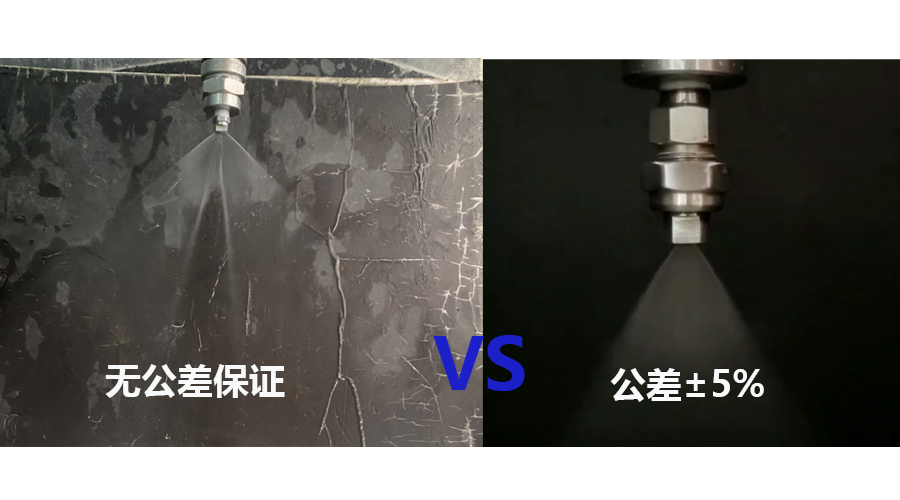

The ultimate pursuit of 0.01 tolerance

The "professional degree" of a professional industrial product manufacturer depends on the tolerance accuracy of the product that is 0.01 or even below, and the nozzle production pays particular attention to the pursuit of tolerance. The impact of 0.01 tolerance gap on the customer's product production is beyond you and I can imagine, "high yield" shows the continuous pursuit of extremely low tolerance on the production of the nozzle behind! On the contrary, the nozzles produced by non-professional nozzle manufacturers, under the concept of no tolerance, the performance of the field production process is extremely poor, "low yield" will be the expected result, "high yield" represents the company's profit and product trust, and the "tolerance" performance of the missing thousands of miles will be the key factor!

1. The flow difference will produce a large vibration condition under the instability of various values on the process performance.

2. The wrong flow rate selection will affect the spraying Angle and flow distribution, and may cause the spraying gap between the spraying nozzle and the nozzle when the nozzle arrangement is fixed.

3. If the flow is too small, there will be insufficient impact. At this time, if you simply adjust the injection pressure, it may not be able to achieve better results.

4. The choice of flow distribution will affect flow distribution and particle size.

5. The particle size of the liquid is too small, which will lead to uneven spraying of the liquid and increase the loss of the liquid:

- The particle size of the liquid is too small, which will easily cause the liquid to be taken away with the gas during the extraction process

- If the particle size is too large, it will not be able to fully penetrate the finer holes, resulting in uneven spraying of the liquid medicine.

Boyuan Spray provides high-precision professional nozzle processing and perfect factory inspection, the most stringent exit inspection to check our products, so that each batch of products have uniform and stable quality performance.